your cryogenic

storage

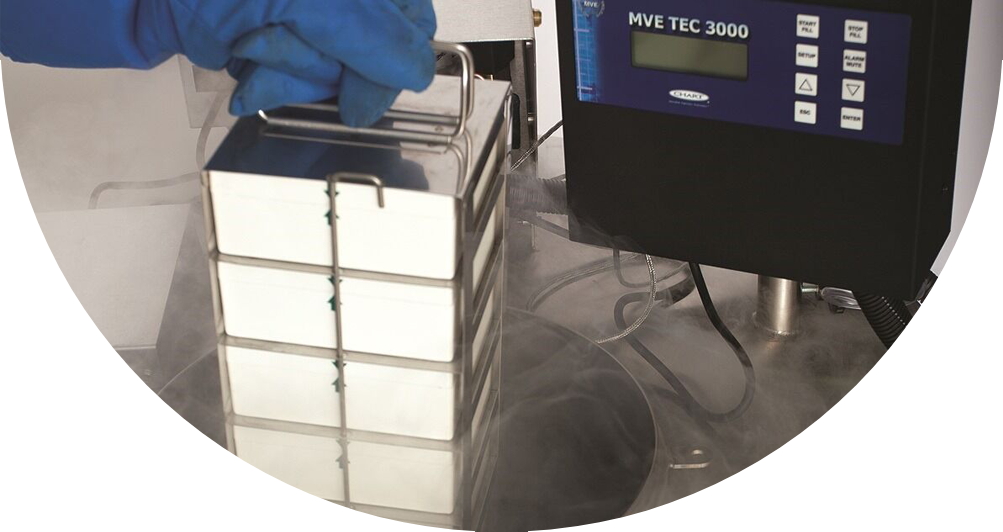

MVE HE 800C Series

For compact, high-performance cryogenic storage

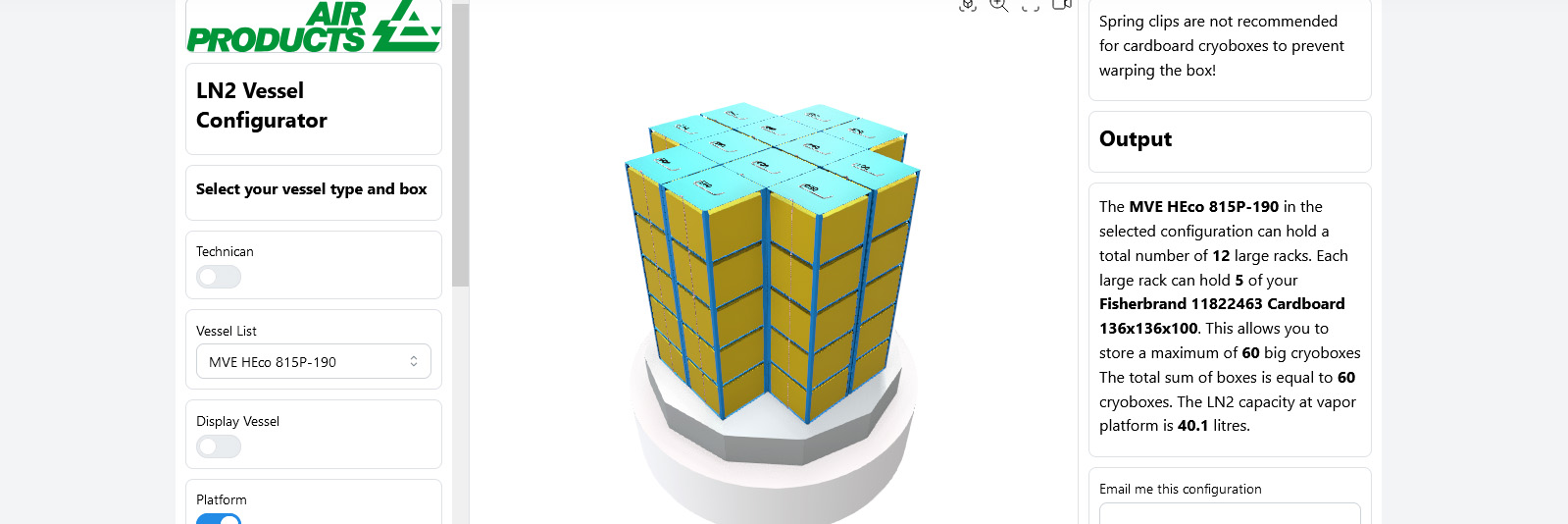

MVE HEco™

Looking for extended hold times and unmatched efficiency? The MVE HEco™ Series has you covered.

Racking solutions

Tagging racks has never been easier. Customise your racking solutions to suit your needs.

Let's rethink what Air Products can do for you...

MDR-Certified Liquid Nitrogen

Storing human tissue samples? Your gas needs to be Medical Device regulation (MDR) certified - and we're the UK's only liquid nitrogen manufacturer to comply.

Learn more

Liquid Nitrogen Supply & Delivery

Whatever your needs, we offer a total cryogenic storage solution using MVE's wide range of liquid nitrogen storage vessels - widely regarded as the best available.

Learn more

Design Consultation

Setting up a new cryoroom or expanding an existing one, we provide a full design and installation service to make sure it works efficiently.

Learn moreOur products

At Air Products, we specialise in providing complete cryogenic storage solutions to perfectly suit your needs. That's why we work with MVE, one of the world's leading suppliers, to provide cryo storage to suit every user.

Liquid Nitrogen Freezers

We offer one of the largest selections of liquid nitrogen freezers in the world.

Industry applications

Cancer Research

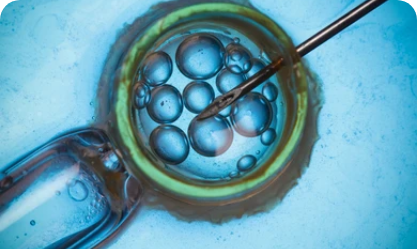

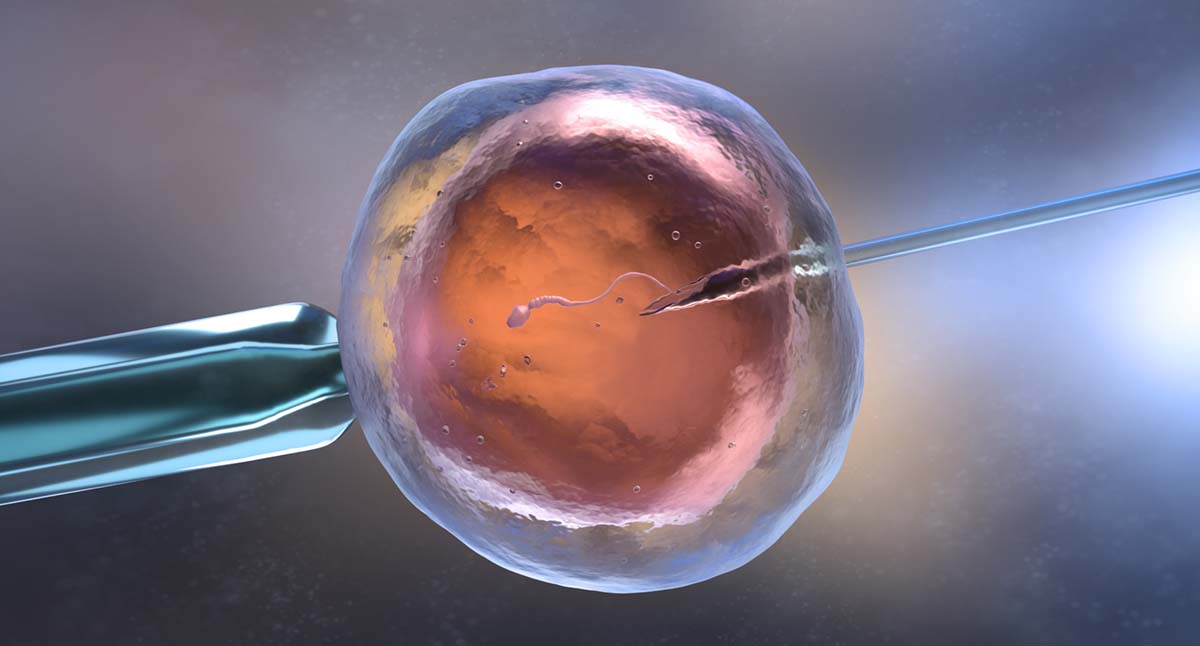

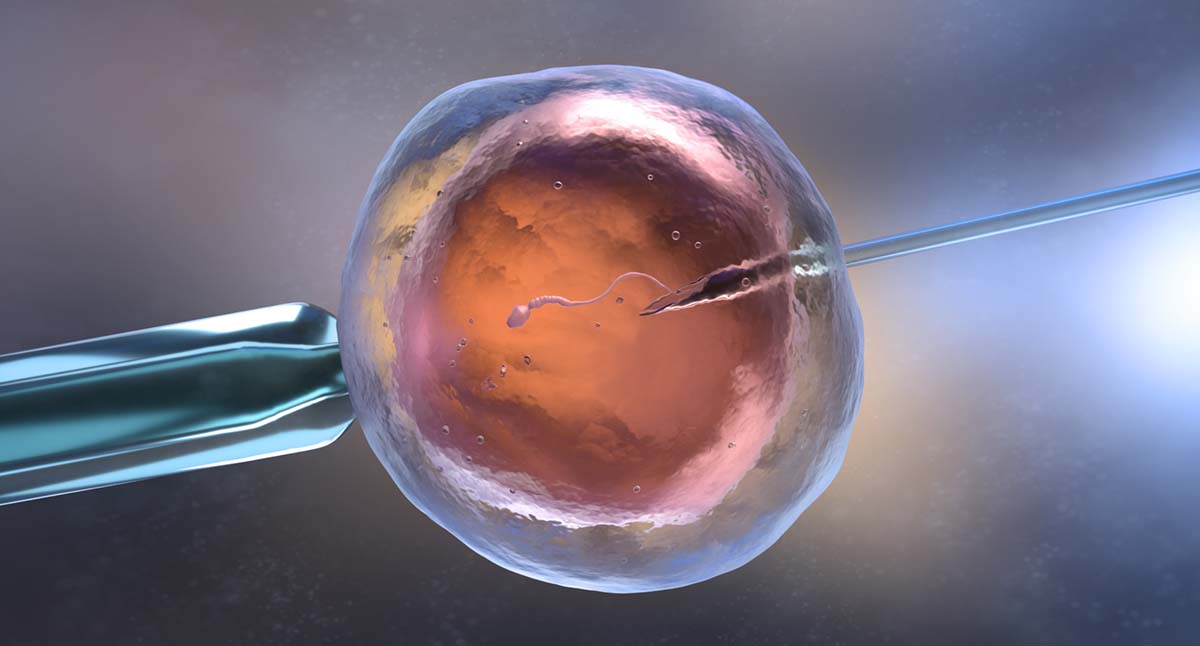

Invitro Fertilisation (IVF)

Stem Cell Research

Vaccines

Cord Blood

Research Laboratories

Animal Husbandry

Looking to make changes to your cryo-room?

Industry applications

We collaborate with laboratories, pharmaceutical firms, fertility clinics, biotechnology companies,

biobanks, research centres, and universities

to drive advancements in the life sciences sector.

Explore market sectors we operate in to discover tailored solutions for your industry. Select your

relevant sector below to find the perfect products to meet your needs.

Invitro Fertilisation (IVF)

Learn moreCord Blood

Learn moreResearch Laboratories

Learn moreAnimal Husbandry

Learn moreStem Cell Research

Learn moreBlood Banks

Learn moreExperts in

cryogenic storage

From IVF to blood banks to research and training programmes, cryopreservation - keeping samples below -135°C to prevent the natural breakdown

of cells and keep sample characteristics intact - has become widely used.

Air Products has over 30 years` experience of helping hundreds of facilities from fertility labs to stem cell research,

so can offer you expert advice on what cry techniques and products will be best for your particular project or

application. Just contact our team today.

The right fit for you and your samples

From gas supply to laboratory design, installation, sample storage, training and ongoing maintenance and support, we're here to help you find the optimum cryogenic storage for your needs. Start by using this interactive selector guide to find the right options for you.

Arrange to speak to

an expert

Complete the form below and one of our experts will be in touch.

Download our

brochure

News

Air Products at Fertility Conference 2025

Racking Configurator

Air Products to Exhibit at Cell UK Congress 2024

Air Products to Exhibit at Lab Innovations 2024

Latest articles

Is your lab as safe as it should be?

Read More

Improve Your Labs Efficiency

Read More

Rethink your cryo-room for improved efficiency and sustainability

Read More

Anthony Nolan's stem cell registry aids blood cancer patients. With Air Products, they enhance cryopreservation to store cells, supporting life-saving treatments.

Read More

Discover expert solutions to optimize your fertility clinics cryo storage, maximizing space and efficiency.

Read More

Is your cryo-room consuming too much liquid nitrogen?

Read More

Are your samples as safe as they could be?

Read More

Long term cost efficiency in cryopreservation

Read More

How long can you store stem cells?

Read More

Fertility sample storage changes

Read More

Cryoroom Project Management

Read More

Is your lab as safe as it should be?

Putting safety first in cryo-labs protects people and samples, boosts efficiency, and helps ensure compliance.

Read More

Rethink your cryo-room for improved efficiency and sustainability

How the location of your cryo-room leads to better efficiency and lower costs.

Read More

Anthony Nolan - The use of cryopreservation in life-saving research

Anthony Nolan's stem cell registry aids blood cancer patients.

Read More

Rethink your fertility clinics cryo storage space.

Discover expert solutions to optimize your fertility clinics cryo storage, maximizing space and efficiency.

Read More

Is your cryo-room consuming too much liquid nitrogen?

Get our expert opinion on how to reduce your cryo-rooms liquid nitrogen consumption. Saving you money and making your lab more efficient and sustainable.

Read More

Are your samples as safe as they could be?

Discover our expert solutions to mitigate the risk of your cryopreservation failing and to ensure the protection of your labs vital samples.

Read More

Long term cost efficiency in cryopreservation

Discover our advice and guidance on how to make your labs cryopreservation efficient and cost effective in the long term.

Read More

How long can you store stem cells?

While most cells in the body are differentiated and serve a specific function, stem cells are undifferentiated, meaning they can develop into many cell types that can serve numerous purposes. These cells are able to divide... indefinitely, and in the process, can either remain a stem cell or transform into a differentiated cell to aid the body.

Read More

Fertility sample storage changes

Anyone that works in the fertility or assisted reproduction industry can't have missed the recent headlines around the storage of fertility samples. Current storage limits are 10 years, after which a storage facility, if the owners haven't elected to donate them, will remove the samples and allow them to perish.

Read More

Frosty Fortunes: Prioritizing Quality

As you contemplate the acquisition of a cryogenic freezer, you may find yourself in a familiar dilemma. Drawn towards the most economical options, you question whether these freezers are actually good value for money.

Read More

Cryoroom Project Management

Managing a Cryoroom project for installation at a medical or scientific facility can be a daunting task with a range of potential obstacles to consider. Air Products Cryoroom Design and Project Management services are here to help you through this complex process.

Read More

How Energy Efficient Are Liquid Nitrogen Freezers?

In facilities such as blood banks, medical research centres and fertility clinics, the safe storage of biological samples is vital. Long term preservation of such fragile samples requires extremely low minimum temperatures of -135 degrees Celsius, alt the way down to -196 degrees Celsius.

Read More

How cryogenics have revolutionised animal breeding

The impact that human beings have had on the lives and development of other animals cannot be understated –while some species have been systematically bred for our purposes, others have been devastated by human colonisation through loss of habitat and hunting.

Read More