Could we be ‘over-freezing’ our food supply and if so, what can we do about it? These were the questions raised at last month’s Cold Chain Summit 2024, where experts affirmed that an industry-wide change in the standard temperature set point for frozen food could drastically improve the sector’s sustainability, saving 17.7 million metric tonnes of CO2 per year globally.

This landmark conclusion came off the back of a recent study commissioned by Nomad Foods, undertaken by Campden BRI. They revealed that reducing the set freezing point from -18°C to -15°C could deliver a 10% reduction in freezer energy consumption, without compromising product safety, nutrition, texture, or taste.

Clearly these are significant findings for the sector. Delivered at scale they could help cut down emissions, safely reduce food loss, and minimise costs for manufacturers. But implementing these changes industry-wide is not so simple. As Birsen McArdle, Value Optimisation Lead at Campden BRI illustrates: “This has the potential to revolutionise the frozen food industry and deliver significant energy and cost reductions for manufacturers and retailers. However, this is not something that we at Campden BRI and Nomad Foods can deliver on our own. Trade bodies, retail partners and other key stakeholders will need to help us to explore opportunities for broader collaboration.

“We envisage next steps in this broader project to include the temperature monitoring of the whole frozen logistics chain, from initial production freezing through to supermarket aisle freezers, as well as how we can support Nomad Foods in sharing their work with the wider frozen food industry.”

The frozen food industry needs a new focus on smart, more sustainable freezing. So, what else can businesses do to help?

Tracking and monitoring

Investing in quality freezing technology is one way businesses can reduce their own energy consumption, maintain consistent and accurate temperature control, and drive down industry-wide emissions. An increase in the use of smart meters and temperature control technology will be on the rise over years to come, helping improve manufacturing efficiency and productivity.

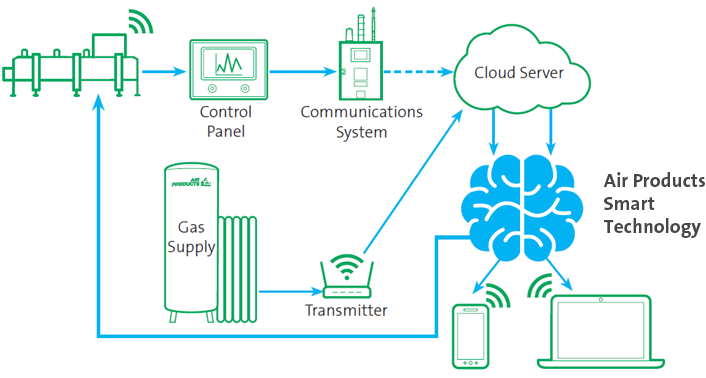

Remote monitoring systems, such as our Air Products Freshline® Smart Technology, connect with cryogenic freezers using wireless communications technology to track process parameters and suggest improvements based on advanced analytics. This allows for the monitoring of operating conditions such as nitrogen usage, helping businesses make more sustainable, cost-saving decisions.

The Air Products Inline Ingredient Chilling System is another such example, with a tailor-made temperature control system designed to accurately cool down dry ingredients and powders during production. These sorts of automated temperature monitoring systems optimise operational efficiency, as well as overall energy and gas consumption.

Collaborations and partnerships

Innovating new technology is one thing, but securing widespread change is another. Businesses and trade bodies of every size and scope must now come together to ensure efficient freezing processes come to the fore in shaping new industry standards.

The UK’s food and beverage sector could take the lead in pioneering industry change towards reducing CO2 emissions. Representative trade bodies such as the Cold Chain Federation are supporting initiatives that explore how a set point change could work in practice amongst their members. These range from capturing members’ views across the industry, to lobbying for broader awareness within Westminster.

On a global scale, the industry-wide coalition Join the Move to -15 is inviting businesses worldwide to build on the work of Campden BRI’s report and explore the feasibility of warming the cold chain.

With the mounting pressures of an ever-growing global population, the need for the sector to cut its emissions has never been greater. This is possible, but not without the support from every player at every stage of the supply chain. From global cooperation to embracing new technologies that reduce energy consumption throughout the production process and maximise efficiency, innovation, and collaboration, a joined up approach will be key to reshaping the sector in years to come.

For more information on the work undertaken by Campden BRI contact Birsen McArdle, Value Optimisation Lead at Campden BRI Birsen.McArdle@campdenbri.co.uk.