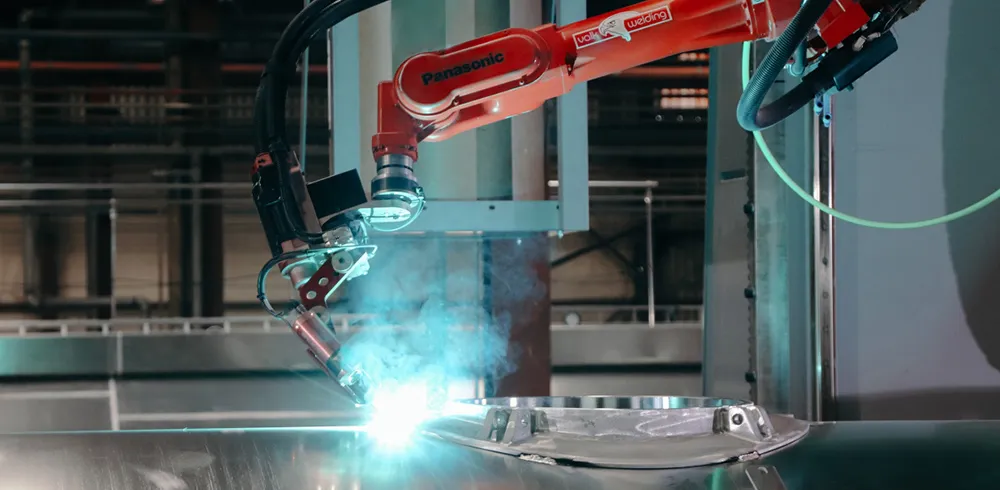

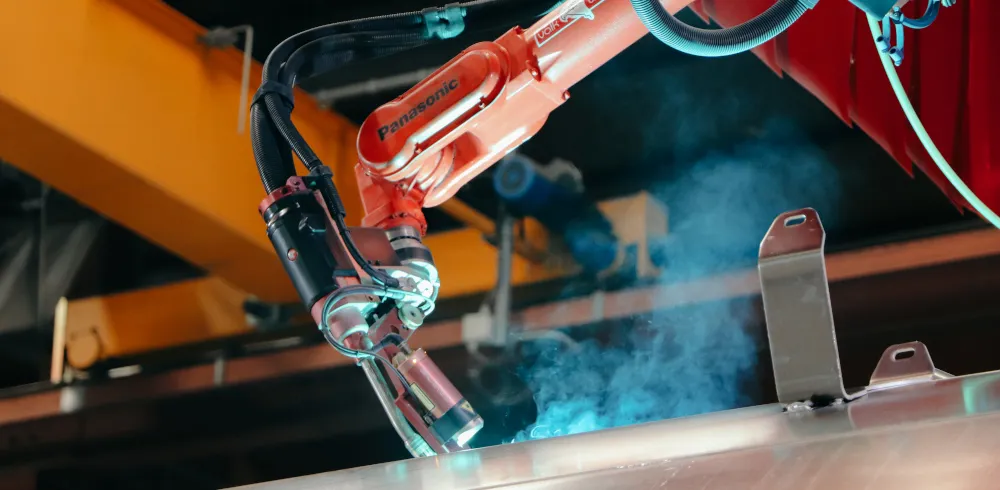

First introduced in the industrial sector during the 1960’s, robotic welding involves the use of automated systems to perform welding tasks. These robots are programmed to execute precise movements, ensuring that the welds are uniform and of high quality. Common applications include arc welding, spot welding and laser welding, among others.

Robotic welding has revolutionized the manufacturing industry by increasing efficiency, precision and consistency in welding processes. It allows manufacturers to streamline operations and maintain high production rates. This automation not only enhances productivity but also reduces human error and improves safety in the workplace. However, the effectiveness of robotic welding is heavily influenced by various factors, one of the most critical being the choice of welding gas.

Welding (or shielding) gas plays a pivotal role in the welding process by influencing the quality of the weld. Different types of welding applications require specific gases to achieve optimal results and choosing the correct shielding gas is vital for several reasons:

Investing in a robotic welding system is a huge financial commitment but one that can significantly enhance production efficiencies, improve weld quality repeatability. The huge advantages of a robotic welding system are only as good as the shielding gas and using a gas developed for manual welding will seriously compromise the welding speed. The ultimate question is why would manufacturers invest heavily in robotic welding systems and then not invest in the best, most suitable shielding gas for their welding applications?

Simply put, failing to select the most suitable gas will undoubtedly compromise the overall effectiveness of the robotic welding process.

One such gas that has been designed with robotic welding is Ferromaxx® Plus from Air Products. Ferromaxx® Plus has been created for MAG welding carbon steel. The specially formulated mixture increases welding speeds, improves weld quality and reduces rejects, gives excellent penetration characteristics and is tolerant to variations in weld parameter settings. Not only does Ferromaxx® Plus give a smooth and flat weld finish, users see reduced clean-up times due to minimal spatter generation.

While the cost of Ferromaxx® Plus may be higher per cubic metre than traditional manual welding gases, it accounts for only approximately 5% of the total weld cost. Considering the advantages of Ferromaxx® Plus, manufacturers can maximise their return on investment of the robotic system by using a welding gas specifically design for this application.

Ferromaxx® Plus is part of the Maxx® range of gases and is available in high-volume 300 bar cylinders and 300 bar manifolded cylinder packs. Purpose-designed for MAG welding carbon, carbon manganese and low alloy steels, the Ferromaxx® gases give superb weld quality and excellent penetration together with minimal spatter and low fume levels.

Air Products also offers other high-performance gas mixtures designed for different material types such as stainless steel using Inomaxx® Plus and aluminium using Alumaxx® Plus. These gases see greater heat transfer which leads to a deeper, more rounded bead cross-section as well as a wider bead, with improved penetration.

Inomaxx®, Alumaxx® and Ferromaxx® form part of the Maxx® gases range from Air Products.

Air Products offers the full range of gas supply options including single cylinders, high volume cylinder packs and bulk liquefied gases.

The high volume 300 bar 47 litre cylinders contain 40% more gas than traditional cylinders and are designed for the larger fabricator. High volume packs consist of 18 manifolded 50 litre cylinders, containing over 50% more gas than conventional offerings. This results in cost savings for larger users by reducing pack changeovers, deliveries and rental costs:

For the largest gas users, Air Products will design and install on-site CryoEase® services or a bulk gas delivery system.

This convenient method of supply enhances productivity, improves safety and reduces cost by eliminating cylinder handling and gas ordering. Air Products manages the project from start to finish and ensures compliance with all relevant national and international safety guidelines and legislation.

Currently, robotic welding is used only on a small portion of building projects. However, with emerging technologies, the trend is likely to change but its success hinges on various factors, including the choice of welding gas. Understanding the properties and applications of different gases is essential for achieving optimal weld quality, efficiency, and cost-effectiveness. As technology continues to advance, the integration of robotic systems with the right shielding gas such as Ferromaxx® Plus from Air Products will play a crucial role in shaping the future of welding in numerous industries.

For more information on Ferromaxx® Plus from Air Products:

www.airproducts.co.uk/gases/ferromaxx-plus

Simply fill in the form below to book a date for your Gastrak® Service review.

Alternatively, you can call us on 0800 389 0202