The service starts with a thorough analysis of your current welding process using independently-calibrated equipment. An Application Specialist from Air Products will identify precisely where you can optimise welding performance and then provide you with a predicted gas consumption saving report, outlining how much you could potentially save. As there’s no cost for this service, you really do have nothing to lose.

Gas control equipment, hoses and connectors need to be regularly inspected and tested to ensure they are safe and free from leaks. Many thousands of litres of weld process gas are wasted every year due leaks.

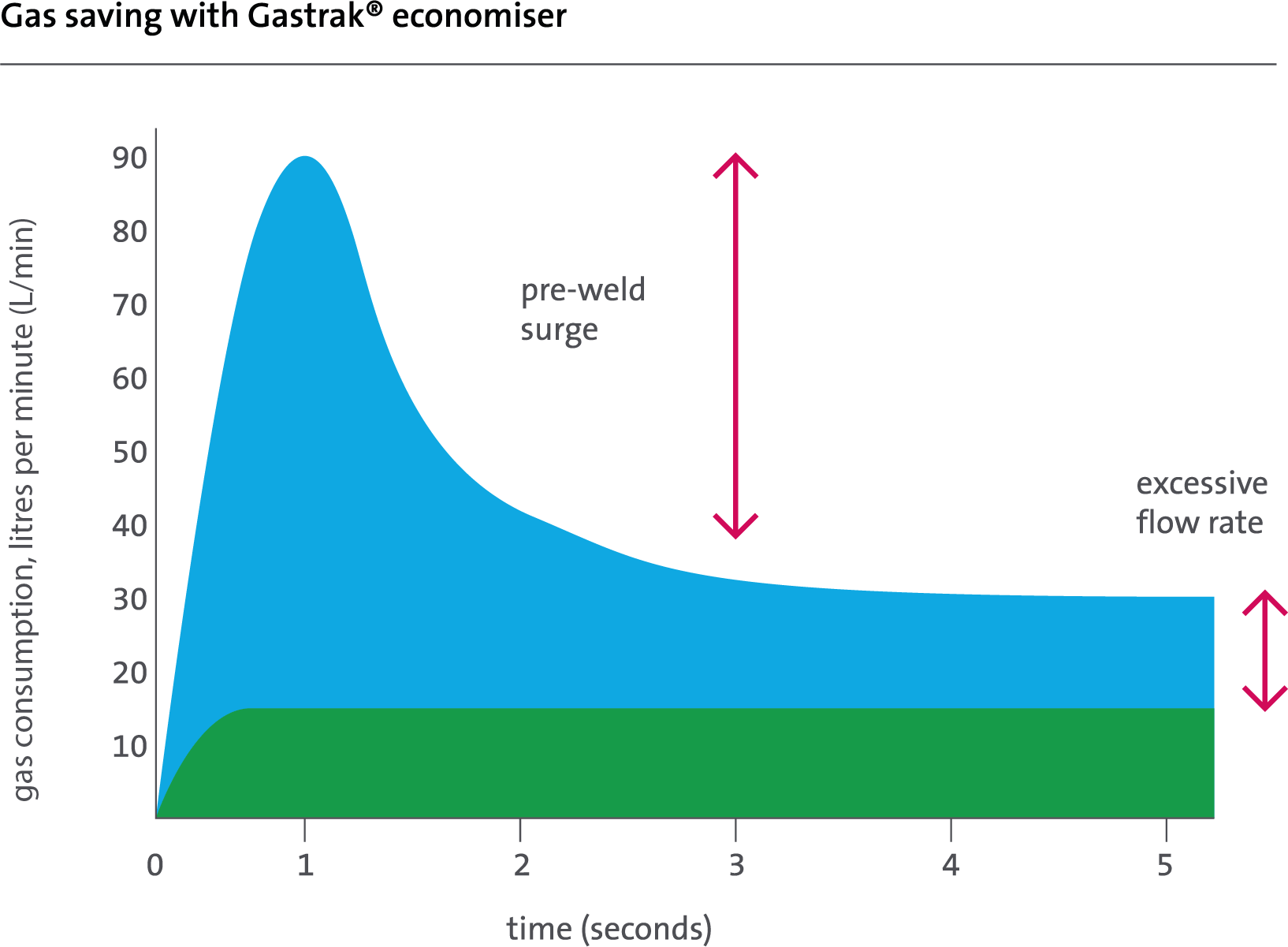

Many welders believe a higher weld process gas flow rate gives a better weld. This is not true. There is an optimum flowrate for each application.

It is common to experience a surge of gas at the start of each weld; this is known as pre-weld surge. It is a waste of gas and can cause porosity.

Once you’ve agreed to the proposals, our team installs Gastrak® Economisers on your welding equipment – there’s no capital investment needed, just a low monthly rental fee. Our Application Specialists will monitor gas usage intensely over the initial two-week period to make sure performance is going to plan, then return regularly – at least every 12 months – to make sure your targets are being achieved. And as a Gastrak® Service customer, you have access to our welding specialists’ expertise any time you need it. It’s all part of the service.

Gastrak® SelectCylinders and pipelines(Air Products) |

Gastrak® e2 ServiceCylinders only(Air Products) |

|

| Recommending the best weld process gas | ||

| Identifying leaks | During surveys | Automated on-demand e2 system |

| Equipment visual inspection report | ||

| Conducting gas efficiency survey using calibrated and traceable equipment |

Simply fill in the form below to book a date for your Gastrak® Service review.

Alternatively, you can call us on 0800 389 0202