Integra® e2 Cylinder

Work smarter,

weld smarter.

A cylinder that saves time, improves quality and embraces sustainability by reducing welding gas consumption.

Buy now Book Your Free Demo

Cost saving

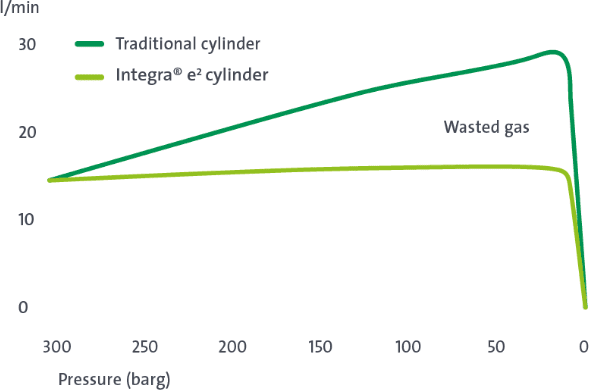

With a built-in regulator there is no need to buy, repair or calibrate a regulator again. Gas flowrate is consistently controlled with the Integra® Flow Optimiser (IFO) ensuring excess gas usage and costs are avoided.

Time saving

Quicker changeover times are possible due to the click on connecting IFO and integrated regulator while the active contents gauge means you never run out of gas mid-weld. Filled at 300 bar, Integra® Cylinders can also last longer than traditional cylinders filled at 200 bar.

Improved safety

The Integra® e2 Cylinder has features built-in to minimise risks associated with handling cylinder, it is lighter than traditional cylinders, more stable due to its lower centre of gravity and the oxygen and acetylene cylinders cannot be operated without flashback arrestors.

Easier handling

Shorter and lighter than traditional cylinders, the Integra® e2 Cylinder is easier and safer to manoeuvre. The welding gas cylinder is fitted with an integrated handle and the cutting cylinders with a rolling knob for ease of handling.

Designed to help you work smarter, weld smarter.

Built-in regulator

Free up time spent attaching regulators. The integrated regulator and Integra® Flow Optimiser do the work for you in minutes.

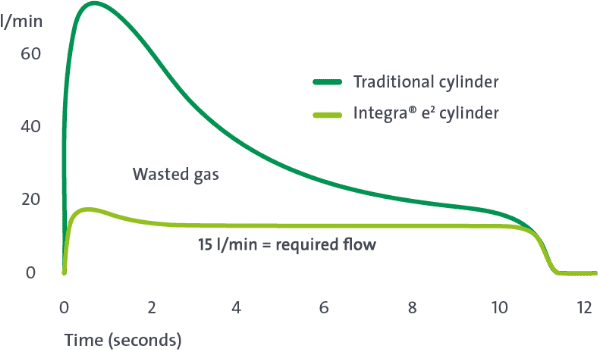

Flow consistency

Unlike traditional cylinders, the IFO means flow is consistent throughout the life of the cylinder to save you even more gas.

Flow control

The built-in regulator, quick connect gas outlet and pre-set Integra® Flow Optimiser (IFO) eliminate set-up time and stop excessive gas waste.

Surge protection

The Integra® e2 Cylinder's unique valve reduces pre-weld surge, to help you save gas and ensure you weld with a consistent flow.

Connectivity

The free Integra® e2 Cylinder app lets you remotely check gas type, leak test status, gas contents, consumption history and remaining arc time, to put you in full control.

Improved safety

Integra® Cylinders are smaller, lighter and easier to handle than traditional cylinders.

Leak detection

The Integra®e2 Cylinder’s push-button leak test ensures you don’t waste even the smallest amount of gas.

Information

The contents gauge always shows how much gas is left and the Integra® e2 Cylinder also has an electronic contents indicator and low-level alarm.

Leak detection

One-touchis all it takes to test your welding machine and hoses for leaks.

Protective valve guard

The ergonomic valve guard incorporates a rolling-knob and collar to make it easier to move the cylinder and place it onto your welding machine.

Electronic contents indicator

Quickly see how much gas remains, even when the cylinder is not in use.

Order online

Prices exclude rental, delivery and collection options – more information

Welding Gases Range

Whether you are MIG, MAG or TIG welding carbon steel, stainless steel or aluminium we have a welding gas in the Integra® e2 cylinder for you.

| MIG/MAG | TIG/PLASMA | ||||||||

| Carbon Steel |

Stainless Steel |

Aluminium & Alloys | Carbon Steel |

Stainless Steel |

Aluminium & Alloys | ||||

| Solid Wire |

Cored Wire |

Solid Wire |

Cored Wire |

||||||

| Ferromaxx® Plus The best gas mixture for faster, cleaner MAG welding of carbon steel. |

● | ● | ● 1 | ||||||

| Ferromaxx® 15 The reliable all-rounder for carbon steel MAG welding. |

● | ● | |||||||

| Ferromaxx® 7 The thin and medium carbon steel MAG welding specialist. |

● | ||||||||

| Inomaxx® Plus The best gas mixture for MAG welding stainless steel. |

● | ● 2 | |||||||

| Inomaxx® 2 The reliable gas mixture for MAG welding thin and medium thicknesses stainless steel. |

● | ||||||||

| Inomaxx® TIG* The best gas mixture for TIG welding austenitic stainless steel. |

● 3 | ||||||||

| Alumaxx® Plus The best gas mixture for MIG and TIG welding of aluminium. |

● | ● | ● | ● | |||||

| MIG/MAG | TIG/PLASMA | ||||||||

| Carbon Steel |

Stainless Steel |

Aluminium & Alloys | Carbon Steel |

Stainless Steel |

Aluminium & Alloys | ||||

| Solid Wire |

Cored Wire |

Solid Wire |

Cored Wire |

||||||

| M21 ArC20 (20% CO2 in Argon) Standard gas mixture for MAG welding carbon steel. |

● | ● | ● 1 | ||||||

| M26ArC020/2 (20% C02, 2% Oxygen in Argon) Suitable for Carbon Steel, solid wire. |

● | ● | |||||||

| Argon Technical Standard gas for MIG and TIG welding. |

● | ● | ● | ● | |||||

| Oxygen and acetylene For cutting, welding and brazing. |

|||||||||

All shielding gases meet or exceed the requirements of ISO 14175.

(1) Flux cored wires (slag forming) (2) Metal cored wires

(3) Austenitic stainless steels only (eg. 300 series)

Find out more about the

Integra® e2 Cylinder

The Integra® range of cylinders is unique. It makes welding more productive, efficient and sustainable, with a host of innovative features providing practical bene

Latest news

Test results Integra® e2 Cylinder at Overlasko Konstruktie

An extensive test series at Overlasko Konstruktie has shown that switching to the Integra® e2 Cylinder from Air Products delivers gas savings of 18-20%.

"We highlighted concerns about handling heavy welding gas cylinders – Air Products listened and acted."

Read how switching to Integra® cylinders helped Allied Vehicles reduce safety risks as well as production downtime.

Book your free demonstration.

Find out how the Integra® cylinders can help you work better and weld better.

Please complete the form to request a FREE on-site demonstration by one of our qualified welding specialists or alternatively call us on 0808 164 8512.

Download our brochure.

Integra® e2 Cylinders Brochure